www.usa-automation.net

17

'21

Written on Modified on

Dunkermotoren News

REALIZING THE SMART WAREHOUSE WITH DUNKERMOTOREN

In the past, the growth curve in the intralogistics sector knew only one direction. Year after year increasing growth rates could be communicated. This is not likely to change in the foreseeable future. The extent to which the Covid-19 crisis will give this trend a further boost cannot yet be estimated. It will definitely influence the market and possibly create new sales markets.

Dunkermotoren has also seen very strong growth in this market segment in recent years. Not only have sales figures risen, but the demands on drive technology have changed in terms of speed, acceleration, weight to be transported, intelligence and safety.

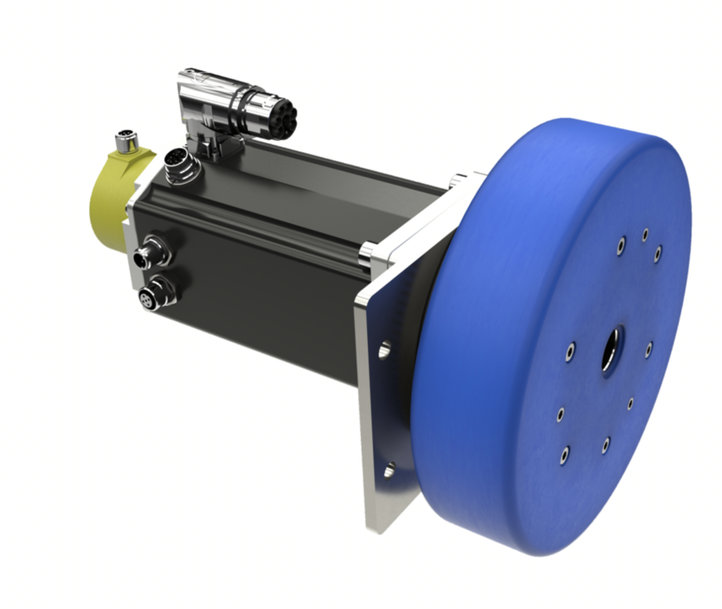

With the BG 95 dPro, Dunkermotoren has a new "strong" motor in its portfolio, which fulfils the above-mentioned requirements in several respects. With a peak output power of 3900 W at a maximum supply voltage of 60 VDC, the motor technology manufacturer has quadrupled the achievable output power of its portfolio.

At the same time, Dunkermotoren has developed a new controller generation for brushless motors, which is used for the first time in the BG 95 dPro. For the motor variants BG 75, BG 66 and BG 45, the conversion to the new generation is also in the implementation phase. With the Motor Control Platform, Dunkermotoren customers have the possibility to configure the control electronics with features specific to the customer and adapt them to the requirements of the application. The bus and Ethernet interfaces are integrated into the motor and mean that no external control unit is required. This saves space at the customer's premises and enables simple commissioning with the Drive Assistant Tool.

In addition to the familiar CANopen communication interface, PROFINET (PROFIdrive application classes 1 and 4), EtherCAT (distributed clocks) and future Ethernet/IP are also available.

As before, motor parameters (e.g. current, temperature, etc.) can be queried cyclically during operation. The new motors feature, among other things, an electronic name plate, an operating hours counter, cycle synchronism and the option of free programming. The dielectric strength of the motor electronics has been improved so that higher battery charging voltages no longer damage or even destroy the motor.

In order not to neglect the safety aspect, the integrated motor electronics will in future be optionally available with STO functionality. In addition to integrated control electronics, customers of Dunkermotoren can also use external solutions. The BGE 5510 dPro is the first control electronics based on the Motor Control Platform and supports all common bus and Ethernet interfaces. With the BGE 5510 dPro, motors up to approx. 250 W can be controlled. The Motor Control Platform and the interfaces provided, form the perfect perfect basis for the IIoT connection of our drives in the Smart Warehouse. We are already working together with our customers and partners on the first digital solutions.

Parallel to the addition of the modular system and the motor portfolio, Dunkermotoren has added the hub gear to the existing gear unit variants. The hub gears of the NG 250 and NG 500 series are used in the traction drive. The transmission is designed in such a way that a maximum load capacity of 500 kg can be achieved without additional bearings.

Dunkermotoren's intelligent motors are used, for example, in shuttles, AGVs, sorting and storage systems. For example, motors of the BG 95 dPro series are used for robots in online supermarkets, or motors of the BG 75 series in logistics centers for parcel sorting.

www.dunkermotoren.com