Compact all-rounder for position measurement

IMScompact complements the existing Rexroth portfolio for absolute position measurement and improves the economic viability of many applications.

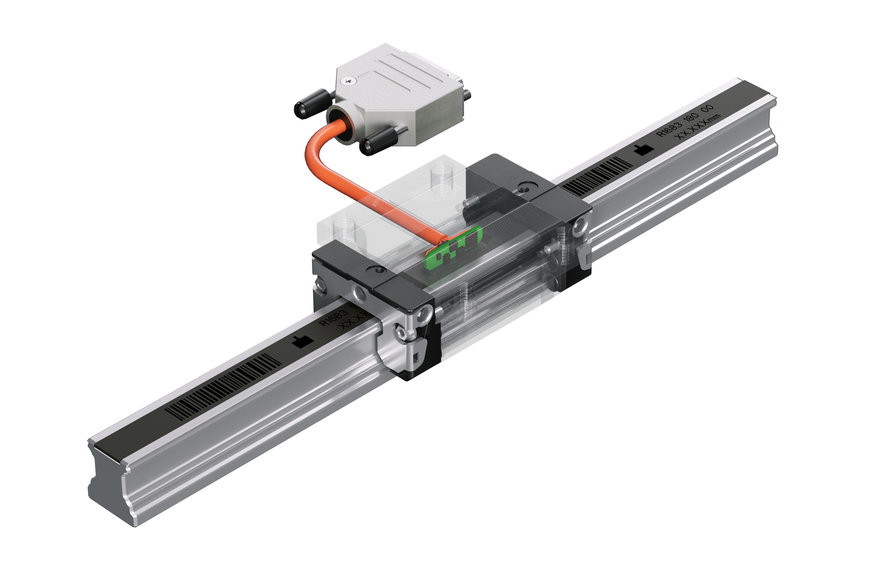

Wide range of applications for integrated absolute position measurement: Thanks to its high level of EMC protection, the new IMScompact can be operated with linear motors among other things.

- Space-saving design: Sensor integrated into the runner block

- Economical position measurements for various product sizes

- Time and cost savings from design to servicing

The integrated IMS position measuring system from Bosch Rexroth is now available as the IMScompact for absolute measurements. The contactless solution with a magnetic measuring principle allows robust and economical position measurement for linear guides of different lengths and sizes and thus replaces all external, linear position measuring systems. A range of applications can now be achieved more quickly and economically: From efficient position measurement in special machine construction to small and large-format applications in areas such as digital printing, battery production and FMCG (fast moving consumer goods).

The new complements the existing portfolio of integrated measuring systems which includes the IMScompact incremental measuring system and two inductive high-end versions for high- precision applications.

The compact measuring systems record the position of the runner block contactlessly with an absolute precision of +/- 20 μm/m and a repetition accuracy of +/- 1 μm at speeds of up to 5 m/s. The measuring length can be up to 17.8 m with rail sections made up of several pieces. Thanks to the high level of EMC protection provided by the sensor which is fully integrated into the runner block, the magnetic measuring system is ideal for use in linear motor axes.

The IMScompact which is available in the sizes 15, 20 and 25 stands out against other magnetic position measuring systems owing to its particularly compact design. Even in the smallest size, the sensor is integrated into the runner block to save space. The key advantage of the absolute measuring function over the incremental one is the fact that the system is ready for use immediately as soon as it is switched on or after a power cut. This increases productivity in many handling and automation solutions.

In initial projects in the field of factory automation, the integrated measuring system has proven itself for compact and economical position measurement in the linear guide without an externally attached linear encoder: For example for measuring workpieces for quality assurance or for recording measurements and further processing via the machine control system.

A second important area of use arises in connection with linear motors, allowing objects to be positioned with high precision over long distances. Examples include print heads in digital printers up to 5 m wide or cameras for the end-of-line inspection of a battery production line.

In a third area of application, the IMScompact proves itself as a low-cost solution for the electrification of conventional hydraulic axes, e.g. when combined with an electromechanical cylinder and servo motor in a fully electric press brake.

Significant time and cost savings over the life cycle

Because the integrated IMS measuring systems combine the functions of linear guide and linear encoder in one system, they require fewer components and take up less space. This reduces the amount of structural design work required. The fully digital selection and configuration process as well as ordering from the online shop help to save even more time.

Thanks to integrated measurement electronics, assembly and commissioning work can also be carried out more quickly. Because the sensors and magnetic strip are supplied already aligned, the measuring head no longer needs to be adjusted on site via the measuring section. To ensure a short time to market, the IMS are available worldwide.

Thanks to the maintenance-free measuring principle, the new IMScompact also reduces operating and servicing costs. If necessary, Rexroth Service can provide quick replacements anywhere in the world and can replace the rail and runner block independently of each other. In order to protect the scale against contamination and damage, Bosch Rexroth also offers an optional cover strip.

www.boschrexroth.com